Chinese Factories Set Up Self-Contained “Bubbles” To Keep Production Rolling Despite Lockdowns

Anybody who has seen the video (censored in China but freely available in the West) of frustrated Shanghaiers and others protesting China’s draconian anti-COVID lockdowns probably understands that, after more than two years of China’s “Zero COVID” policy, the country’s workers have nearly reached their breaking point.

China is in a tough spot 😬 pic.twitter.com/HqzepoBapi

— Gabriel Hébert-Mild™ ⓥ (@Gab_H_R) March 24, 2022

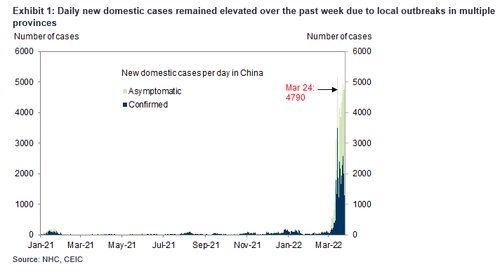

Unfortunately for them, the CCP’s best efforts have failed to subdue to daily COVID case numbers, which continued to climb late this week, with yesterday’s daily tally nearing 5K once again.

Fearful of the economic chaos that more lockdowns could unleash, President Xi recently instructed local authorities to shift to a more “targeted” approach to COVID restrictions, with the goal being to find a healthy medium that balances the CCP’s stated priority to protect the lives of its citizens without sacrificing economic growth.

Most recently, this has led Chinese authorities to try a new approach. According to the FT, manufacturers across China are preparing to transform their factories into isolated “bubbles” that can continue to operate for weeks, even during government-ordered lockdowns, by forcing workers to quarantine at work instead of at home.

The practice reportedly began in southern Guangdong Province, and is presently spreading throughout China. In some cases, hundreds of workers have essentially been forced to live in on-site dormitories – all to keep the production lines rolling.

Bosch Unipoint, one of the world’s biggest car part manufacturers, was able to maintain production at its factory in Longgang District in Shenzhen because about 200 workers agreed to live at dormitories on site during a week-long lockdown this month. “Their commitment to help the business survive this week was amazing,” said Marco Morea, Bosch Unipoint general manager in China, adding that the plant had co-operated with its most critical suppliers to put in place stocks of essential materials before the lockdown began.

“People called to ask how we were still producing,” Morea said. Bosch Unipoint has now launched similar preparations at plants in other cities to cope with potential future lockdowns. Morea said the company aimed to ensure that its brake pad factory in eastern Nanjing city, which has 500 employees, would be able to operate for four weeks even in a lockdown as strict as Shenzhen’s. “We have already start getting raw materials and organising beds for staff in order to be prepared,” he said.

When no dormitories were available, some workers were simply forced to sleep on the factory floor…

In Shanghai, where there have been localised movement restrictions on individual residential compounds, some workers have opted to sleep on factory floors in order to make sure they can get to work and so continue to get paid.

…with only a thin piece of cardboard as a mattress.

One female Dongguan Fuqiang worker who chose to stay at the factory said that instead of a tent she found space on the factory floor for six days. “We all slept over at the plant with cardboard serving as a mattress,” she told the Financial Times.

As a team of Goldman analysts explained earlier this week, the alternative could be the loss of an entire percentage point of annual GDP growth – or worse.

Tyler Durden

Fri, 03/25/2022 – 21:20ZeroHedge News